Oil and gas companies must have accurate measurements and obey all guidelines in order to precisely report the volumes of oil and gas products that they produce. The production accountants that report these volumes need to have the correct information from the field to do this.

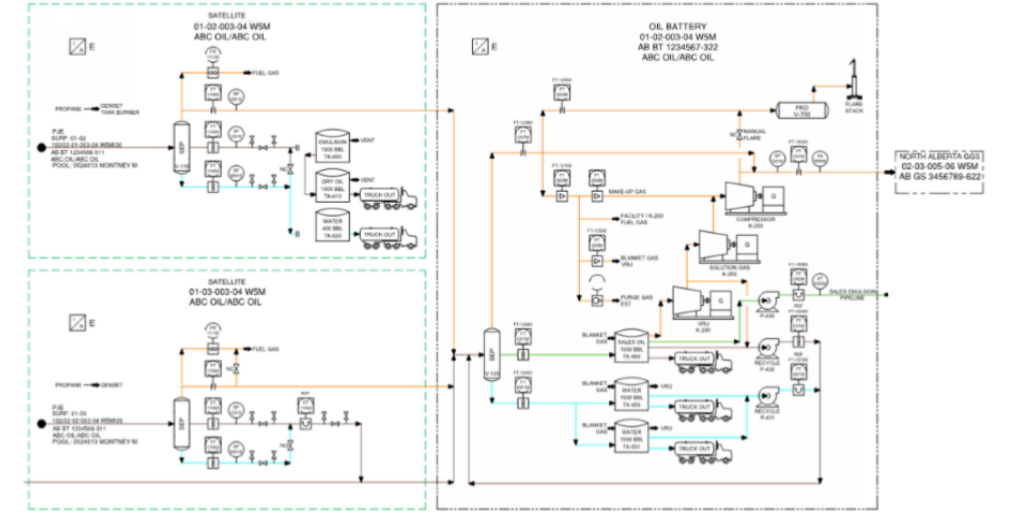

One vital tool that is used by both operations and production accounting to accomplish accuracy is the metering or measurement schematic, which is a visual tool that displays the flow of production from the wellhead to sales or disposal. It indicates flow from left to right and shows all related equipment at each location.

Measurement Requirements

Measurement schematics are required for all active facilities. Schematics for reactivated facilities must be updated within three months of reactivation or after the implementation period. Upon request third parties, operators must provide schematics to the licensee of the subject facility, the company performing the volumetric reporting, the company that performs the product and residue gas allocations, the AER (or equivalent,) and the operator of receipt or disposition points.

Requirements for wells:

- Include all producing, water source, injection/disposal and shut-in wells reporting event for wells with downhole commingled zones

- Identify mechanical lift

- Identify suspended wells (optional)

Requirements for process equipment:

- Include normally closed valves that can change production flow.

- Identify if compressors are electric or gas drive.

Measurement point requirements:

- Identify non-accounting meters if shown.

Storage tanks and vessels requirements:

- Include for these tanks, vessels and caverns fluid type (eg. oil, emulsion, condensate, plant product, waste or water); tank and vessel capacity may be shown on a separate document and should be available upon request.

- Identify if the tank or vessel is underground or default to aboveground.

- Identify optional non-reporting chemical storage or pop tanks if shown.

- Identify if the tank or vessel is tied into a vapour recovery system (VRU) or flare system.

Measurement Reporting and Compliance

When there are physical changes to locations or equipment that affect reporting, they must be recorded on the measurement schematic. These changes need to be communicated with production accounting immediately so that reporting for the current period will be correct.

Physical changes such as wells being added, suspended or shut-in, piping changes or equipment changes require updates.

Temporary changes within the same reporting period don’t require an update to the measurement schematic.

The master copy of the measurement schematic must be updated at least once per year to reflect any changes. Verification of the revisions is required even if there were no changes. The AER Volumetric and Infrastructure Requirements, the Measurement Requirements for Oil and Gas Operations, as well as How to Submit Volumetric Data to the AER contain the rules for allocation of lease sites and geographic areas into reporting facilities.

All gas and liquids received and delivered from a facility must be continuously or batch measured in a single phase. Wells and associated equipment are only linked to and reported under batteries or injection facilities, gas wells must be linked to and reported under gas batteries and crude oil/bitumen wells must be linked to and reported under crude oil/bitumen batteries.

The disposal wells must be linked to and reported under disposal facilities, injection wells are linked to and reported under injection facilities, and source water wells can be linked to a battery but are more commonly linked to the injection facility. Measured and prorated wells should not be linked to the same battery. Facilities using either regenerative sweetening processes or hydrocarbon liquid recovery processes must be reported as gas plants if the produce greater than 2.0 m3 /d of hydrocarbon liquid.

Measurement Schematic Consulting by Intricate

Metering or measurement schematics ensure accuracy and compliance with all requirements. It’s crucial to have the proper tools and services on hand so that measurements and reports are displaying the correct information. Intricate has spent over 12 years building, updating and validating metering schematics for more than 70 oil & gas producers, to design and build a system that works in the real world.

Contact us at sales@intricategroup.com or 1-587-760-1616.